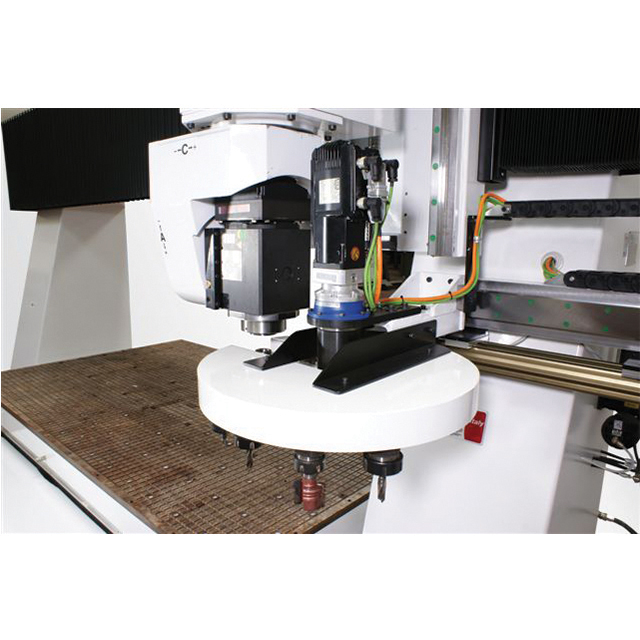

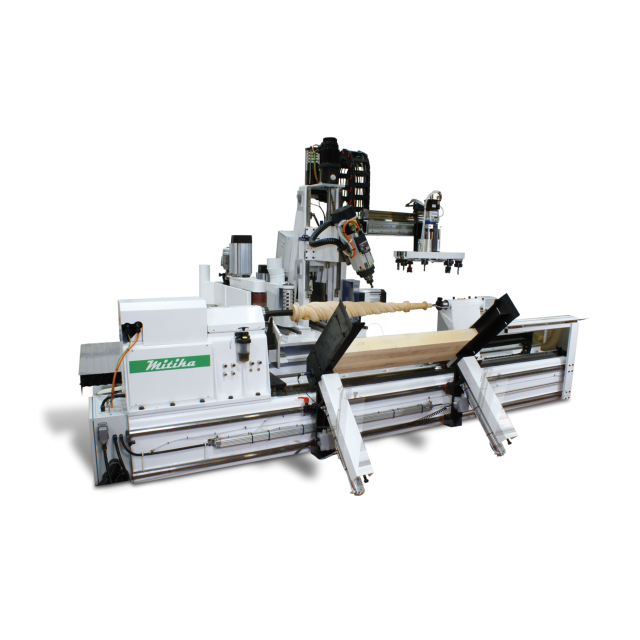

Greda Argo 5 Axis CNC Machining Centre

Features

- 5 axis CNC machining center

- Heavy duty fixed bridge structure

- Working bed running on over-sized hardened guides

- Single or twin working table to allow simultaneous machining/ loading

- Range of table types and clamping systems available for working different materials

- Additional multi-spindle boring unit options

- Easy programming though standard Windows based operating system

- Custom sizes and configurations available to suit individual production

call 0115 986 5201

Description

The Greda Argo is a 5 axis CNC machining center engineered for processing both simple and complex work including boring, mortising, tenoning, shaping, finger jointing, routing etc. A range of table types are available including;

FT – Matrix vacuum table for sheet material or fixing separate clamping/ pods

AL – Aluminium table with T-slots for securing custom jigs etc

AT – Longitudinally adjustable crossbars complete with clamps and vacuum pods for further flexibility in material clamping

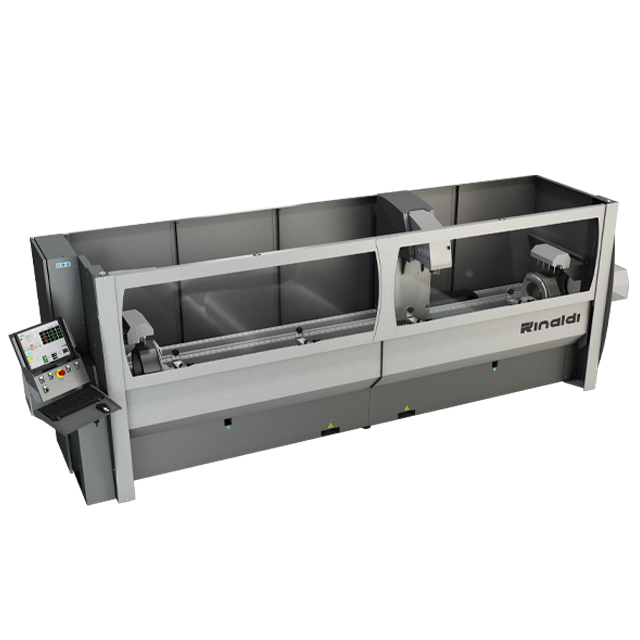

A range of further options including automatic tool changers, automatic tool length measurement and calibration, multi-boring units, 6th axis rotary tailstock and headstock, mobile operator console etc are available as required.

All Greda machinery can work with the majority of existing CAD CAM suites. Optimisation and anti-collision systems with 3D graphical representation of the machine movements can be added to the specification.

Specification

| Number of axes | 5 (6 as option) |

| X axis movement | 2700 / 3600 mm |

| Y axis movement | 1800/ 2600 mm |

| Z axis movement | 700/ 900 mm |

| A axis rotation | +/- 110° |

| C axis rotation | +/- 220° |

| Maximum speed of movement | 1500 mm/ sec |

Literature

Disclaimer

Our suppliers have a policy of continuous product development and improvement, specifications are therefore subject to change without notice. We can accept no liability for discrepancies in specifications or illustrations contained in our publications or the publications of our suppliers.