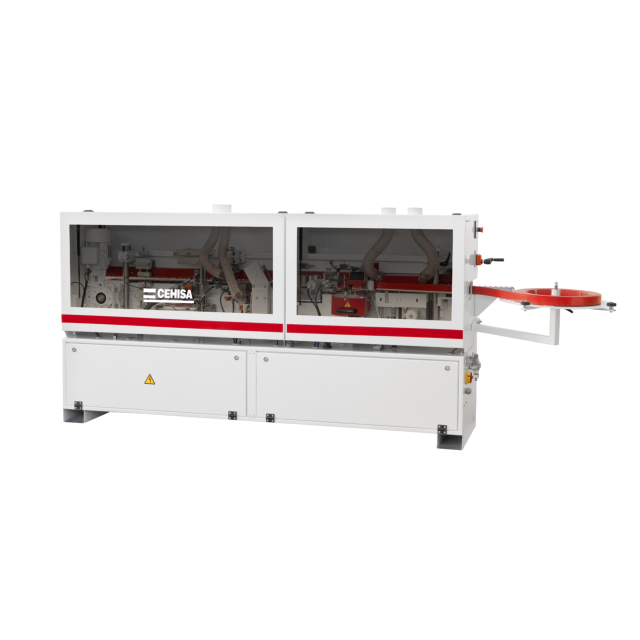

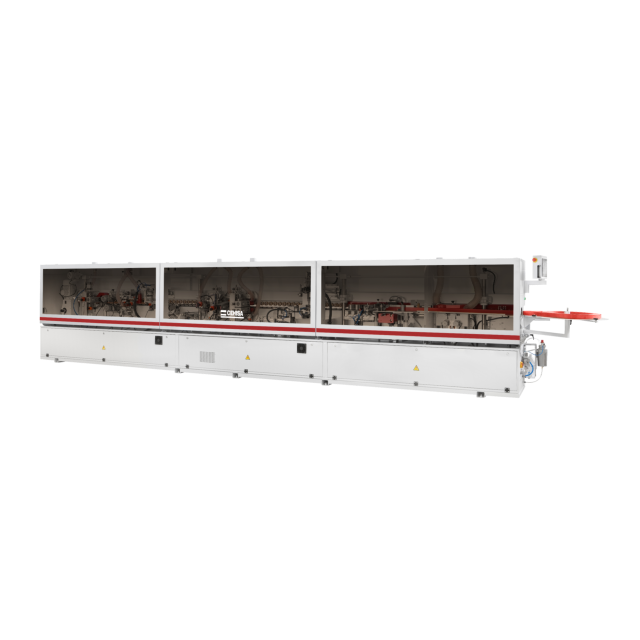

CEHISA Pro Edgebander

Features

- High capacity edging performance

- Automatic unit setting options

- Hot melt glue application

- Touch screen control

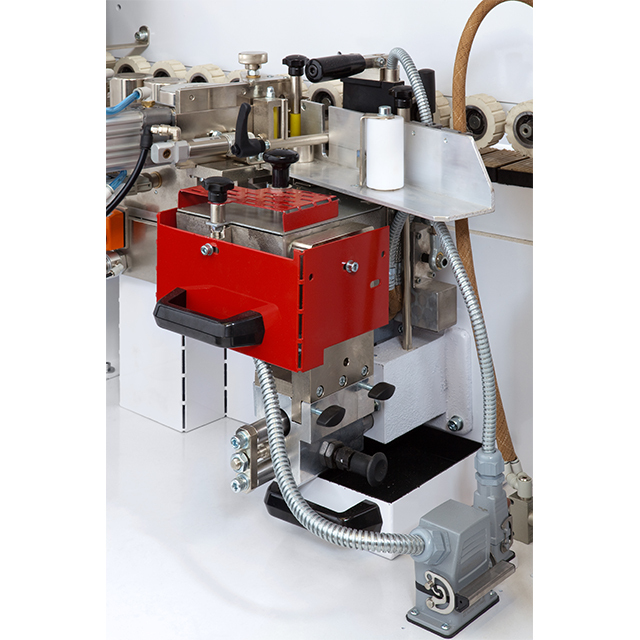

- DUO-MELT glue pot option for EVA and PUR adhesive

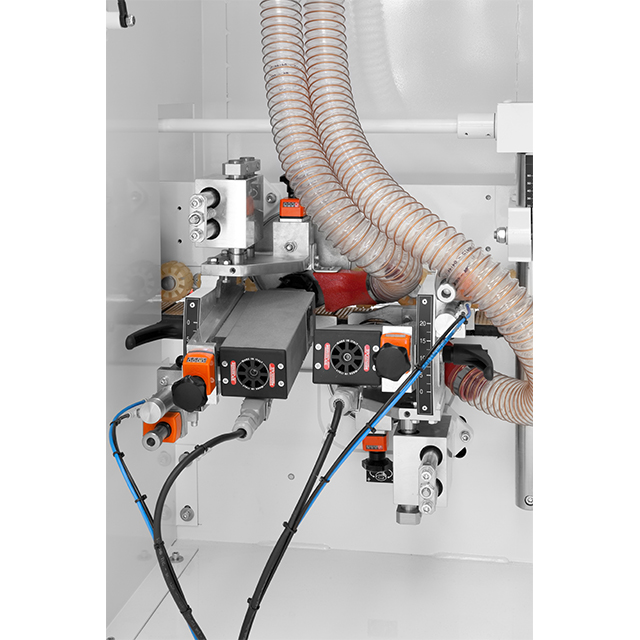

- High frequency motors with independent inverters

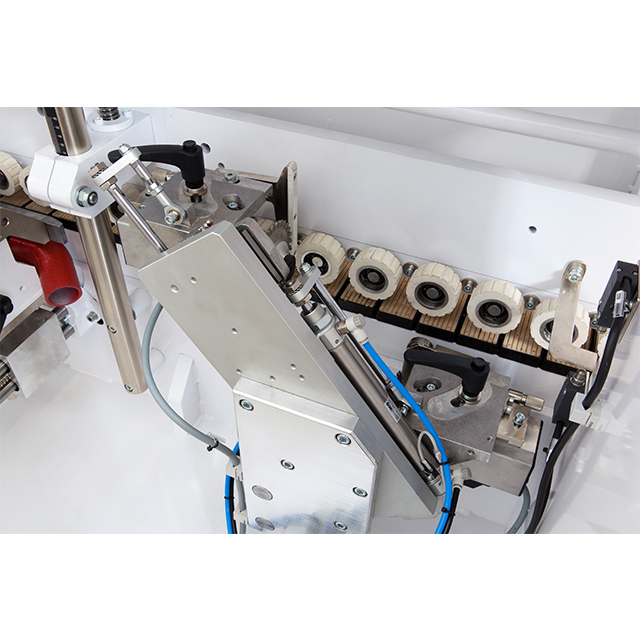

- Synchronised pressure beam

- Air cleaning to tracers

- Fully enclosed working units

call 0115 986 5201

Description

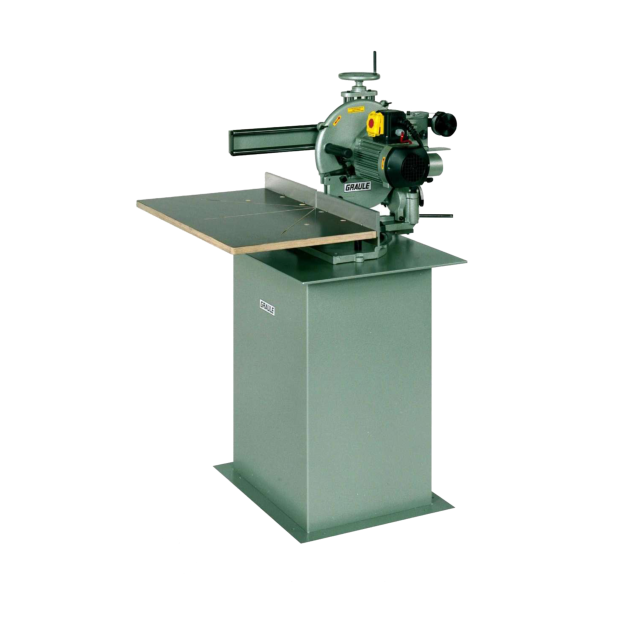

The CEHISA Pro range of CEHISA edgebanders are designed for higher volume panel processers with increased feed speeds and automatic program selection. Designed for ultimate processing efficiency the Pro models are designed to meet the highest demands of quality and flexibility. The optional Air Jet edging system provides seamless adhesion between edge and board with an absolute zero glue line.

Available in 9 separate models offering additional working units, the Pro range can be tailored to your exact production requirements with pre-milling, twin sets of top and bottom trimming units, corner rounding unit with two independent working units for the front and rear of the panel, radius scrapers, glue scrapers, buffing unit and grooving unit.

The Pro is suitable for melamine, PVC, ABS, PP and veneer edging up to a thickness of 3mm and solid edge lippings up to 8mm fed either individually or by optional automatic magazine. The optional DUO-MELT glue pot allows use of both traditional EVA and more technologically advanced PUR adhesives featuring a quick drain cleaning system for removing residual glue with minimum fuss.

The optional pneumatic quick set function allows each working unit to be instantly adjustment between 2 or 5 settings for instant change over between different tape thicknesses. Combined with the intuitive touch screen control, the operator can quickly recall set ups with the need for accessing the machine. The touch screen also provides access for monitoring all machine functions – start/ stop, program editing, parameters check and editing, alarm diagnostics etc all in real time.

Up to 60mm thick panels can be fed through the machine. An industrial chain-track system running on ground steel guides with non-marking traction pads ensure a positive feed without damaging the panel surface while the synchronised top pressure beam with two sets of rollers keeps the panel secured against the track. The track is electronically synchronised to activate each working unit without the need for physical triggers.

Specification

| Edging material thickness | 0.4 - 3 mm |

| Solid edging thickness | 8 mm (auto feed option) |

| Panel thickness | 8 - 60 mm |

| Panel length | 120 - unlimited |

| Panel width | 75 mm - unlimited (60 mm - unlimited optional) |

| Feed speed | 9 & 14 m/min |

| Working pressure | 6 - 7 kg/ cm2 |

| Power | 3 phase/ 1 phase |

Literature

Pro

Disclaimer

Our suppliers have a policy of continuous product development and improvement, specifications are therefore subject to change without notice. We can accept no liability for discrepancies in specifications or illustrations contained in our publications or the publications of our suppliers.