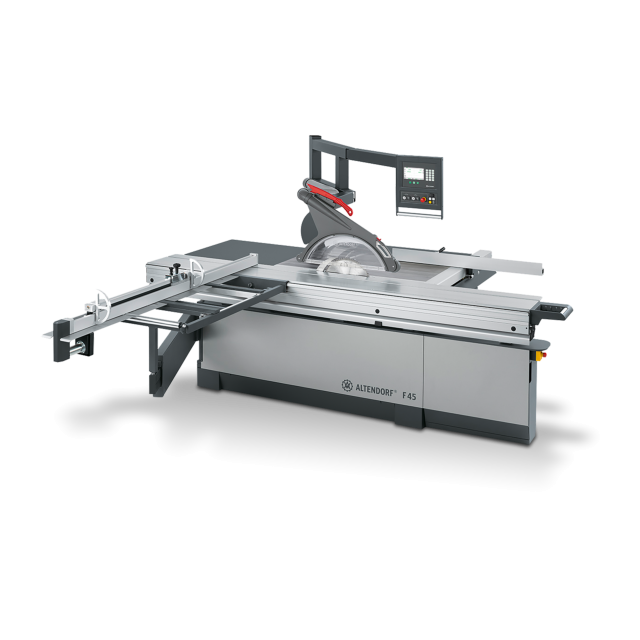

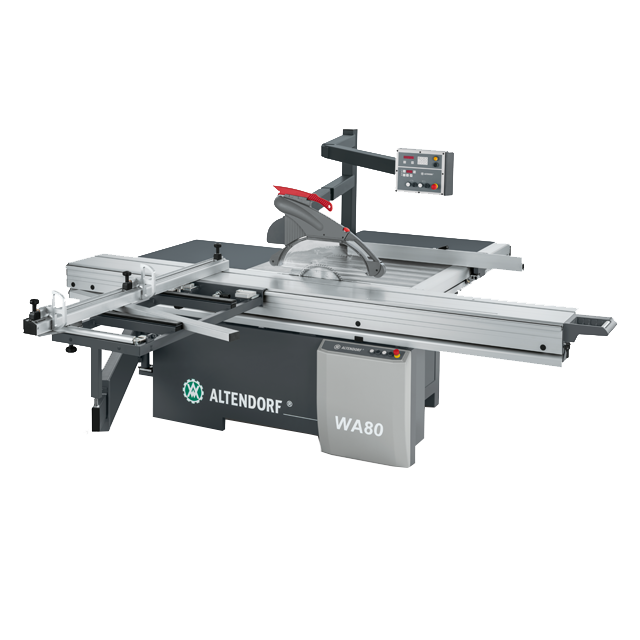

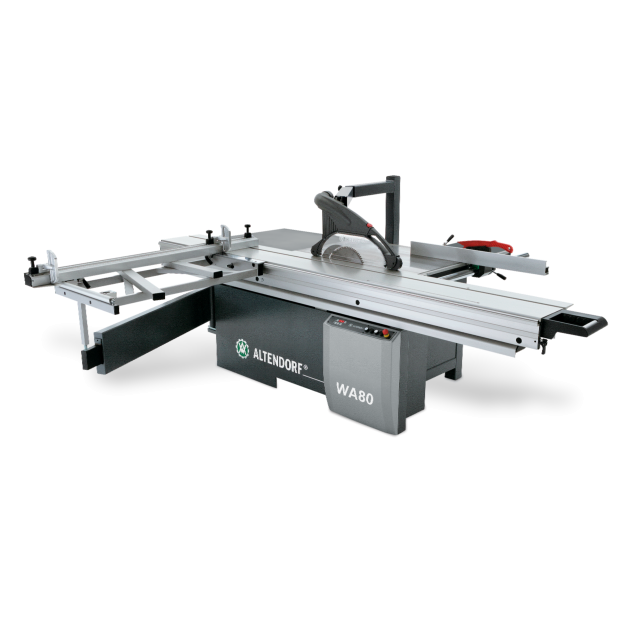

Altendorf F45 Panel Saw

Features

- Choice of ProDrive, EvoDrive or ElmoDrive controls

- Manual, digital or CNC fence options

- Highly configurable

- Eye-level control panel

- Programmable tilt angle

- Programable blade height

- Up to 205mm depth of cut

- Optional 2 way tilt

- Overhead crown guard with extraction port

- AKE quick change saw blade system

- Choice of sliding table lengths

call 0115 986 5201

Description

The F 45 is the flag ship model from Altendorf, and has long been regarded as the pinnacle of sliding table panel saw technology. The machine is available with a choice of eye-level control units; ProDrive, EvoDrive and ElmoDrive. Each system provides offers increasing levels of intelligent control to assist the operator in machine setting, calculation and adjustment. Beyond the control unit, the choice of options continues to give customers the most customisable sawing solution on the market.

Employed in a range of industries the Altendorf F 45 can be equipped for machining an extensive range of materials from solid timber and wood based panels, to plastics, non-ferrous metals and composites.

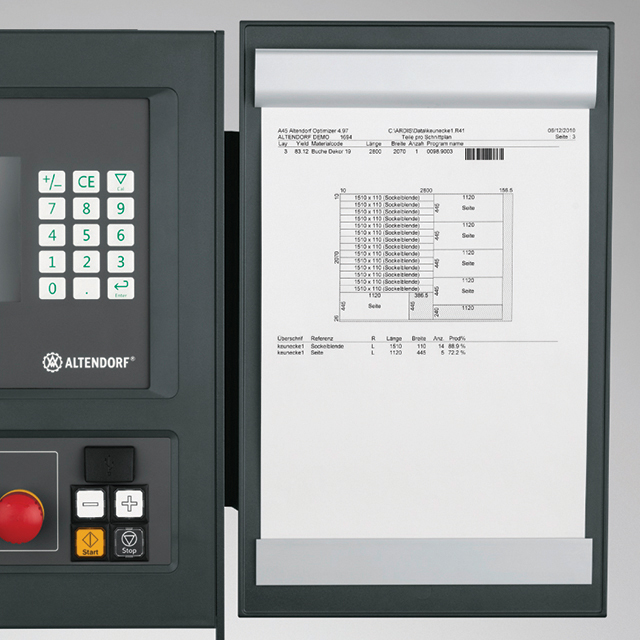

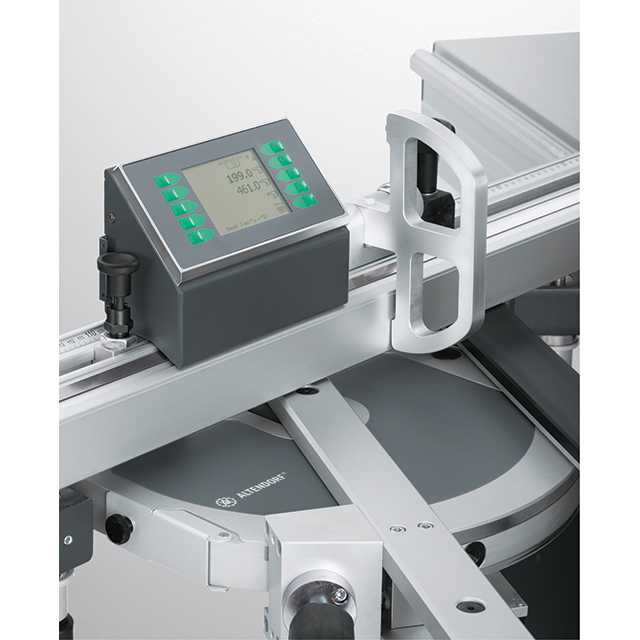

Control

Complete freedom of choice is available when configuring your F 45. Every option is available with every control unit.

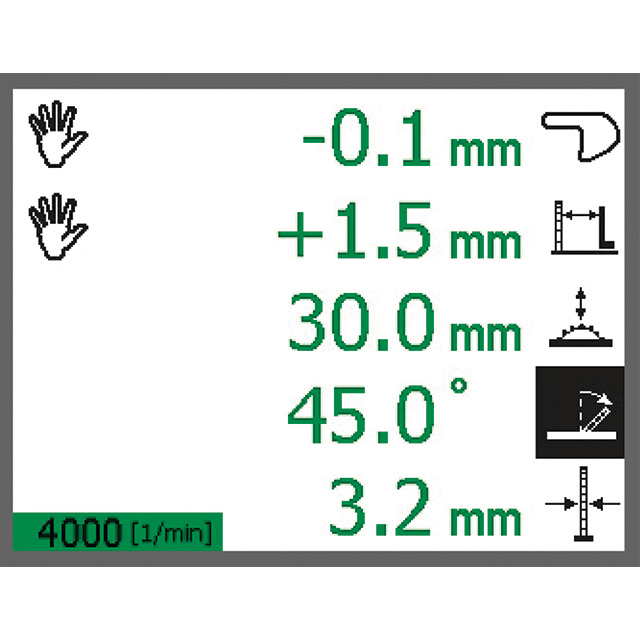

ProDrive – although technically the entry level control unit, the ProDrive provides control over all four working axis. Clearly labelled function keys and numerical key pad give allows the operator to quickly set the saw height, angle, CNC rip fence position, crosscut fence position, scoring saw unit and variable blade speed depending on the configured options. Any combination of settings can be saved and recalled for repeat set-ups.

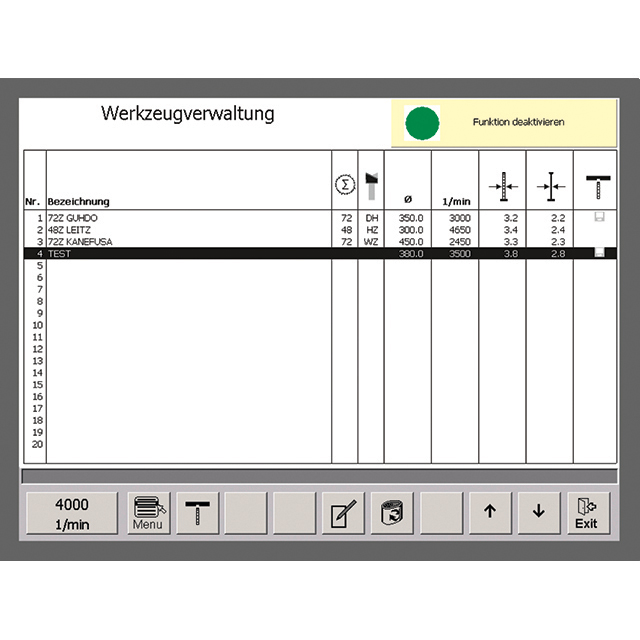

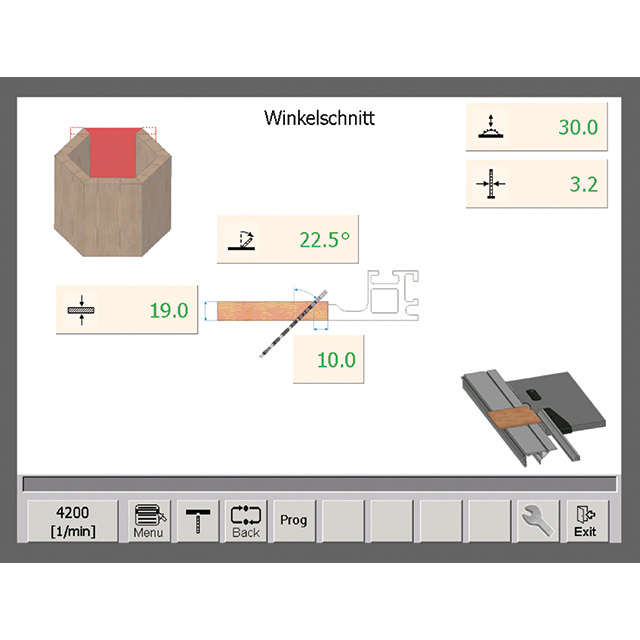

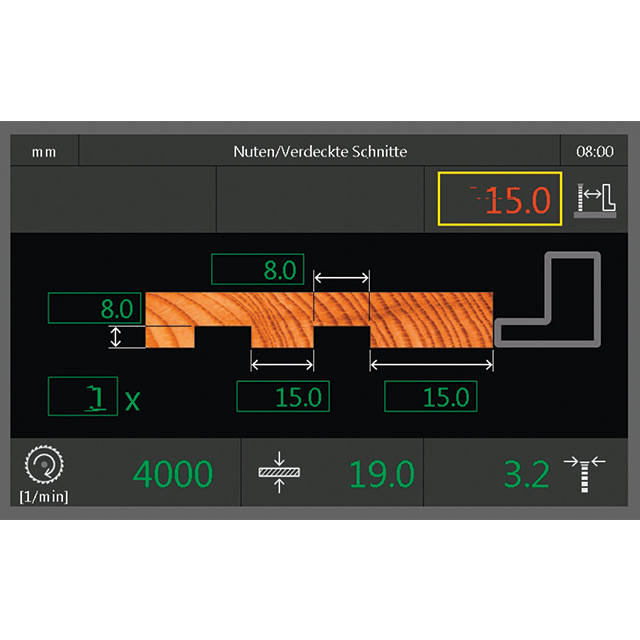

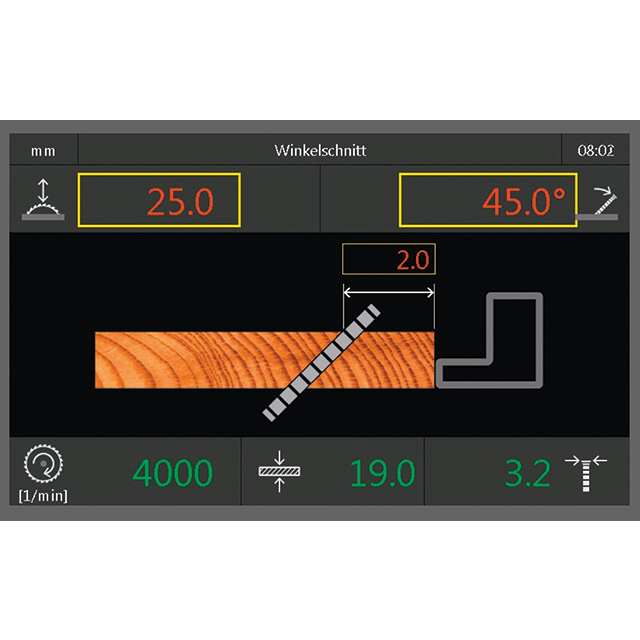

EvoDrive – this all new control unit features a 7” colour touch screen with separate numerical pad for entering dimension settings. Key to the EvoDrive is the array of pre-installed applications. For example, it can calculate inside and outside dimensions based on material thickness and cutting angle. Incremental dimension, groove and bevel rip functions, tool management and compound mitre settings all simplify the operators cutting routine.

ElmoDrive – the most technically advanced control system for sliding table panel saws. The feature rich 12” colour touch screen provides intuitive control with graphical representations clearly displaying all the machines functions. Hot keys can be configured to recall regular settings. In combination with a cutting list optimisation package (such as Ardis) the machine will display cutting lists for the operator to work through.

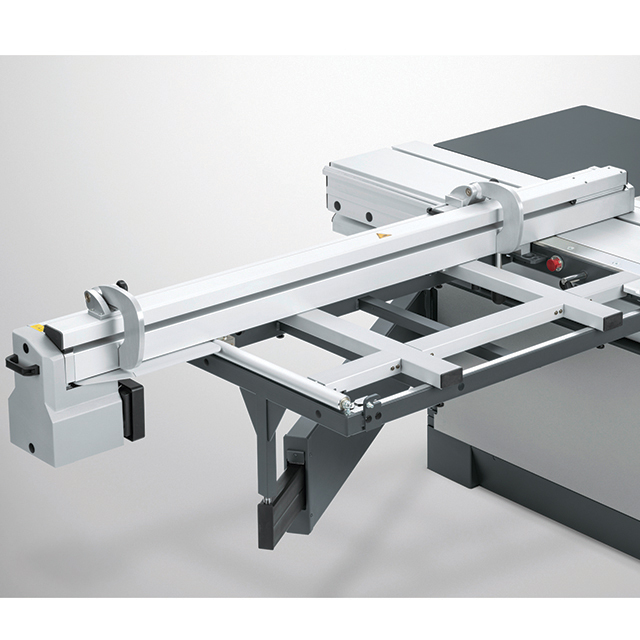

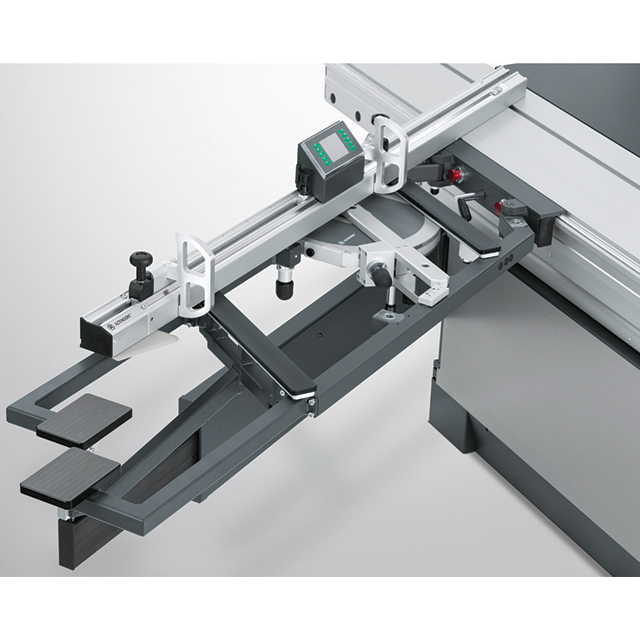

Sliding table

Altendorf have poured over 111 years of research and development into their sliding table system. Dumbbell style rollers ride on hard wearing chromed guidance track resulting in silk like movement for reliable and accurate cutting. Cleaning brushes mounted to the upper section of table, continually remove dust and debris from the guidance rails with no need for lubrication. The table can be locked in any position along its length when required.

The aluminium table features multi-chamber construction for optimal tension and rigidity. Surface ground tables can create a suction effect when equally flat panels are placed on top making it hard for the operator to manoeuvre the material – think about two planes of glass stuck to one another. To overcome this, Altendorf take considerable time in planing each table creating a precision ripple effect on the surface allowing panels to run smoothly across the table.

The standard table length is 3000mm, but can be reduced to 2250mm to save space if required. For larger cutting capacity tables lengths of 3200mm, 3400mm, 3800mm, 4300mm and 5000mm can be specified.

Unique to the F 45 is the option for TIP-SERVO-DRIVE. When working with heavy work pieces the sliding table powers itself through the cut needing no physical effort from the operator other than finger top control of the servo control.

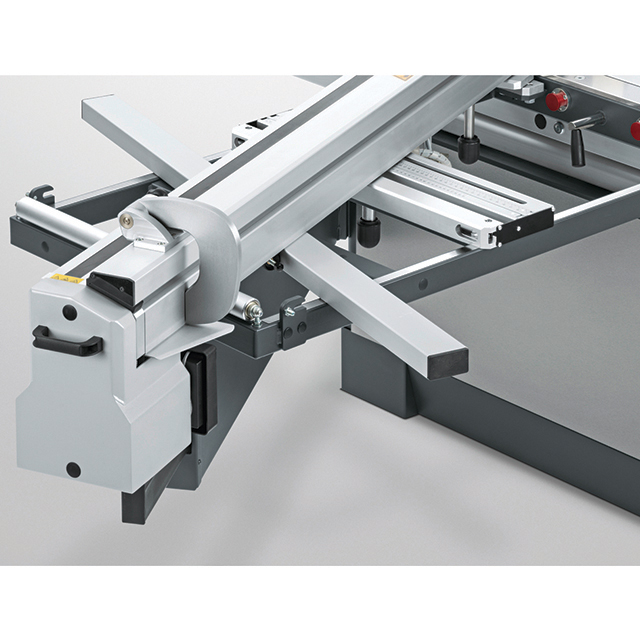

Rip fence

A choice of three styles of rip fence are available on the Altendorf F 45, each with capacities of either 800mm, 1000mm, 1300mm and 1600mm.

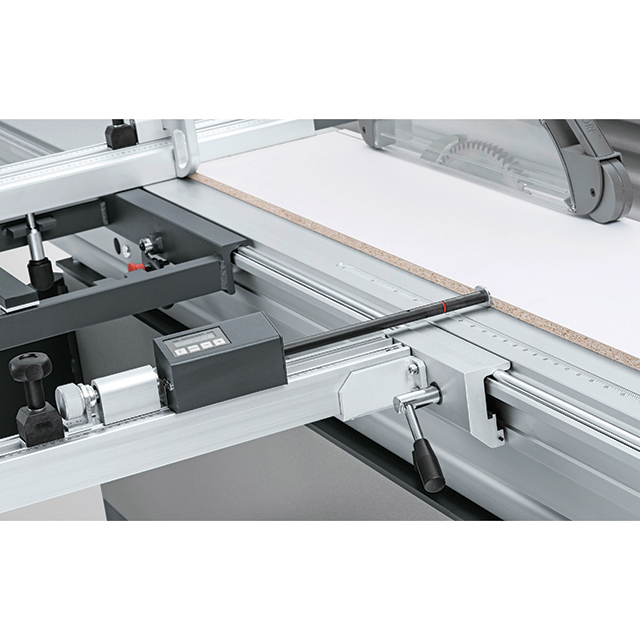

The standard manually operated fence runs smoothly across the hard chrome-plated fence bar for precise positioning using the fine adjustment setting.

For accurate repeatability no matter the operator, the optional DIGIT X fence provides an electronic digital readout mounted directly onto the fence itself. When the fence is changed from its upright to flat position the digital readout automatically adjusts to compensate.

For reduced set up times and improved accuracy the CNC rip fence offers ultimate efficiency and ease of use. Moving at 250 mm/sec the fence quickly adjusts with an accuracy of +/- 1/10mm. The high precision ball spindle and motor are incorporated into the aluminium front section keeping them protected. The fence recognises when it is in the standard upright, or flat position and compensates accordingly.

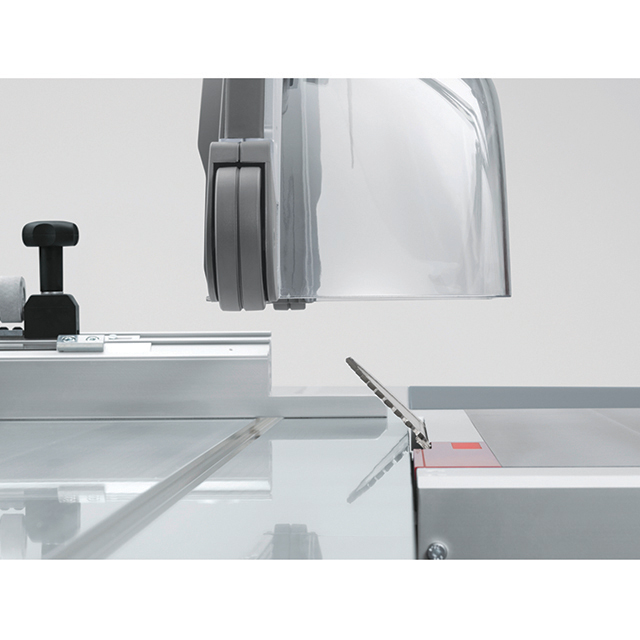

The safety clearance of the optional CNC-driven rip fence in front of the saw blade is 180 mm for all Altendorf F45 sliding table panel saws. To make this zone even safer, Altendorf has placed a sensor in the saw unit’s tilt segment to tell the controller whether the saw blade has been tilted or not. If the sensor detects that tilting has not taken place, the fence can even be moved and positioned up to 50 mm in front of the saw blade at high speed. If the sensor detects even just a slight tilt, the CNC rip fence is braked to creep speed as it approaches its specified end position only under constant manual confirmation by the operator.

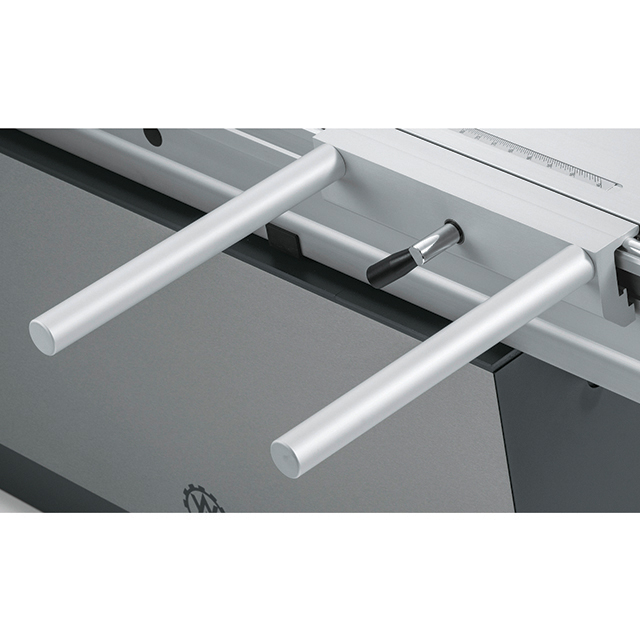

Crosscut fence

As standard the F 45 is supplied with a fixed 90° crosscut fence that can be quickly positioned either at the front or back of the cross-slide support. Two ‘zero play’ flip over stops can be independently set using the incremental scale with telescopic extension up to 3200mm.

For mitre work the optional crosscut-mitre fence is available with a working range of 0 – 49°. Integrated length compensation means that the distance from the saw line to the flip over stops remains accurate when the fence is angled.

Additional options for DIGIT L and DIGIT LD add electronic digital readouts to the flip over stop position and fence angle with a repeatable accuracy of 1-10mm on length +/- 1/100° for angles.

For maximum working efficiency consider a CNC controlled crosscut fence. The UNO 90, DUO 90 and DUO FLEX provide automatic programmable setting of one or two flip over stops all controlled from the eye-level panel.

The frequently used DIGIT L crosscut fence is now even more user friendly: Altendorf’s design engineers have moved the scale closer to the operator to make it easier to read when pre-setting the dimension. Two new magnifying glasses also help to improve readability, enabling pre-settings to be made 30% faster. In addition, the process reliability of the DIGIT L has been increased: the tape measure now also protects the signalling magnetic tape against damage and wear. These optimisation features for the DIGIT L help to increase the productivity and life of the system.

Saw unit

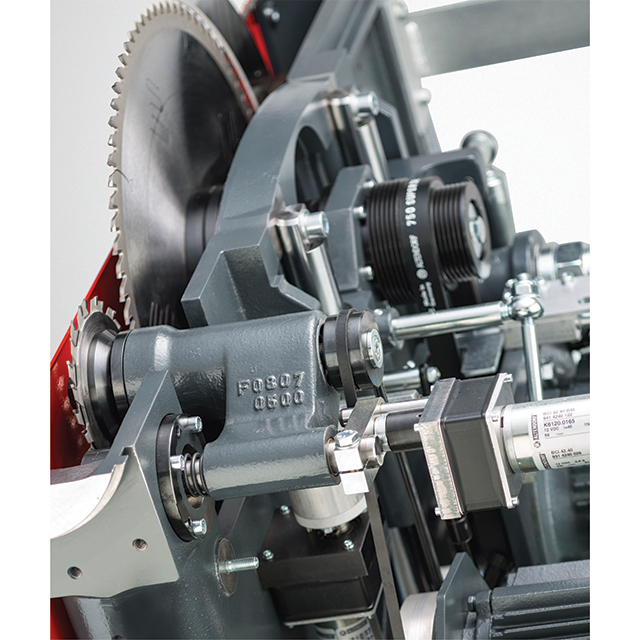

If the F 45 control unit is the brain, then the saw unit is the heart of the Altendorf. The latest manufacturing techniques are used to ensure high precision movement, and reliable performance. The electronically balanced saw shaft runs smoothly with extensive use of cast iron components for vibration free cutting.

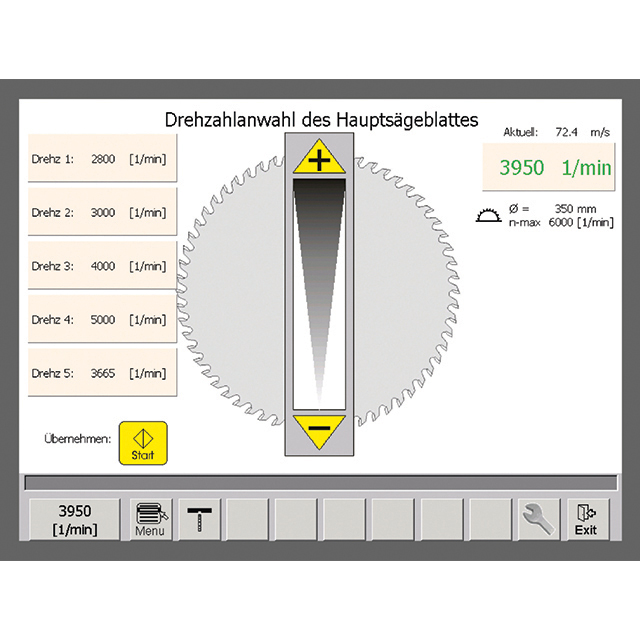

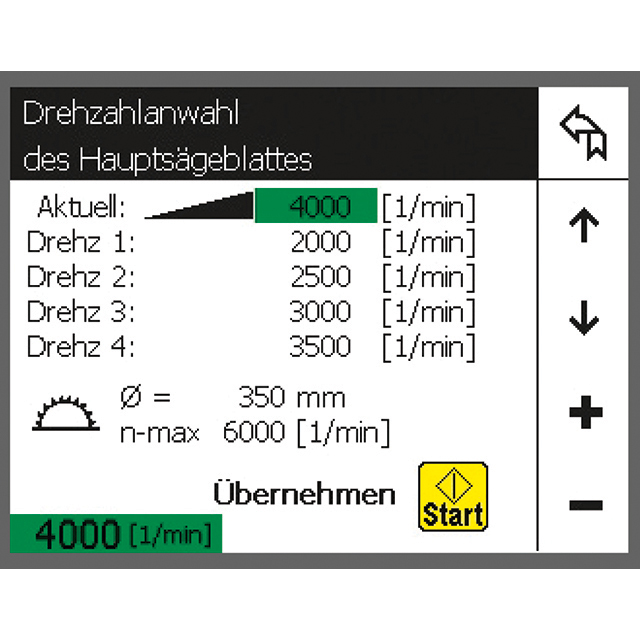

The F 45 now features a cutting depth of 150mm as standard, or 205mm with optional extended cutting height feature. The standard single speed (4000 rpm) 4 kW (5.5 HP) motor can be increased to a three speed (3/4/5000 rpm) 5.5 kW (7.5 HP), 7.5 kW (10 HP) or 11 kW (15 HP) motor as required.

A new addition to the F 45 package is optional two way tilt allowing the saw unit to pitch 46° in either direction. Included is the VARIO speed control offering infinitely adjustable saw speeds from 2000 – 6000 rpm.

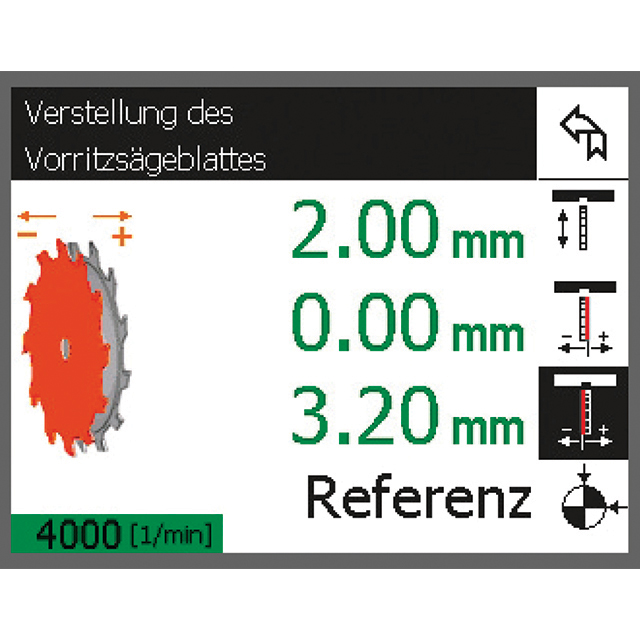

Scoring saw unit

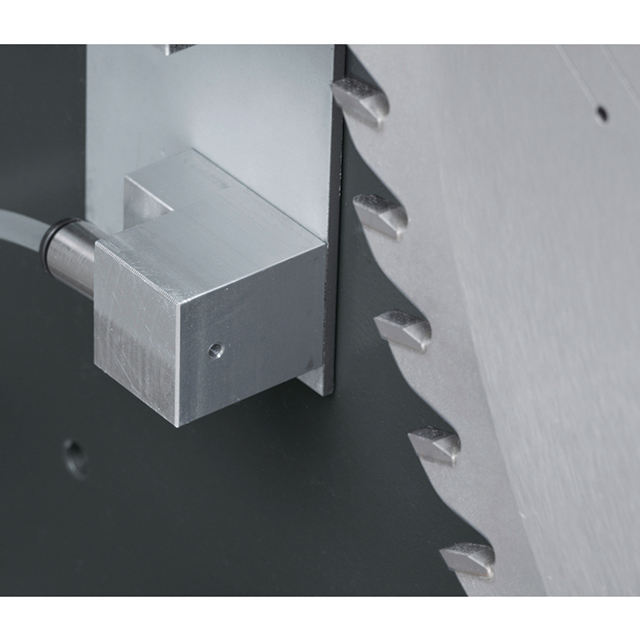

A dedicated scoring saw unit can be added to the Altendorf F 45 to prevent breakout on the underside of laminated materials. The two axis controlled system, powered by an independent 0.75 (1 HP) motor, automatically rapidly raises to its working height when started, and retracts beneath the table when stopped. Add three axis control for electronic adjustment of vertical, lateral and cutting width adjustment.

Optional equipment

In addition to the optional features already described above, the Altendorf F 45 is available with a host of additional options. Contact a member of our team today to discuss the full range in detail. Some of the more common options are as follows;

RAPIDO scoring system – this quick set scoring saw can be adjusted to match the main blade without the need to remove it from the machine. Compared to working with traditional shims the RAPDIO saves up to 10 mins taking about 3 minutes to set.

Parallelogram cross-slide – for regular mitre cutting this system allows the entire cross-slide to be angled with the fence ensuring optimal work piece support is maintained. An electronic digital display shows the angle position to an accuracy of 1-100°.

Single-sided mitre fence – this independent mitre fence locks quickly onto the sliding table for precise cutting of mitres.

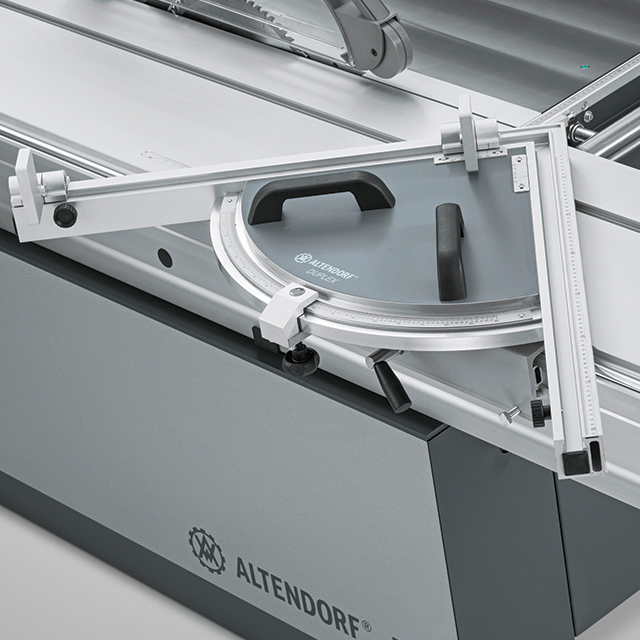

DUPLEX double-sided mitre fence – a separate high precision mitre fence that can be quickly mounted to the WA6 sliding table with angle adjustment from 0 to 90°. When set at 45° mitre cuts can be made on both sides of the work piece without having to adjust the fence. Length compensation allows for precise measurements to be made from the saw line to the flip over stops.

DUPLEX DD double-sided mitre fence – in addition to the features found on the standard DUPLEX, the DD incorporates a large electronic digital display for the angle and stop positions for fast, high precision setting.

Laser cutting line – clearly displays the sawing line in front of the blade when cutting to marked jobs or adjusting material for trimming.

Palin – this additional side fence allows long, thin work pieces to be accurately set for parallel ripping or conical cutting.

Pneumatic pressure beam – long thin materials can be securely clamped along the length of the table, close to the saw line. It is pneumatically operated with two separate clamping zones.

Manual quick action clamp – easily positioned along the length of the sliding table firmly securing the work piece.

STEG second support – easily mounted on the side of the sliding table providing additional support for wider materials.

Infeed roller support – a 300mm wide infeed support roller that can be quickly folded away when not required. Useful when cutting longer materials against the rip fence.

Air cushion table – Another optional feature: the compressed-air unit operates on the right-hand side of the saw blade to make working on the rip fence easier. It the frictional resistance between the material and the machine table by up to 80%. Customers that cut material with sensitive surfaces to size (high-gloss coatings, lamination sheets etc.) benefit from the almost zero contact movement of the workpiece over the machine table.

Parking of the scoring saw unit – Customers who choose the three-axis scoring unit when buying a new Altendorf F45 will automatically benefit from a new parking position. The scorer can be moved vertically and horizontally out of its working range, making it possible to fit main saw blades with a diameter of 450 or 550 mm without having to allow for additional set-up times for the scorer.

Optional working heights – Although the working heights for sliding table saws have slowly risen over the years, there has also been international demand for lower machines from Altendorf. The company has responded to this and now offers three working heights for the F45 sliding table saw: 85 cm, 88 cm and the standard 91 cm.

The next step

Contact us for latest pricing, expert advice or to book a demonstration on the Altendorf F 45 sliding table panel saw.

Specification

| Maximum blade diameter | 450 mm or 550 mm option |

| Sliding table length options | 2250 - 5000 mm options |

| Maximum depth of cut | 150 mm or 204 mm option |

| Blade tilt | 0 to +46° or -46 to +46° |

| Blade speeds | 3000/ 4000/ 5000/ variable rpm |

| Saw to fence capacity options | 800/ 1000/ 1300/ 1600 mm |

| Saw to crosscut fence | 2500/ 3200/ 3500 mm |

| Motor (main) | 4 - 11 kW options |

| Power | 3 phase |

Literature

F45

Disclaimer

Our suppliers have a policy of continuous product development and improvement, specifications are therefore subject to change without notice. We can accept no liability for discrepancies in specifications or illustrations contained in our publications or the publications of our suppliers.