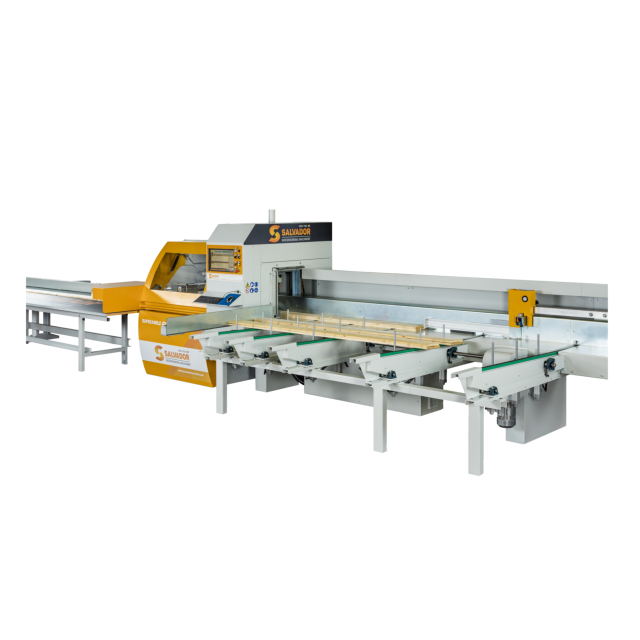

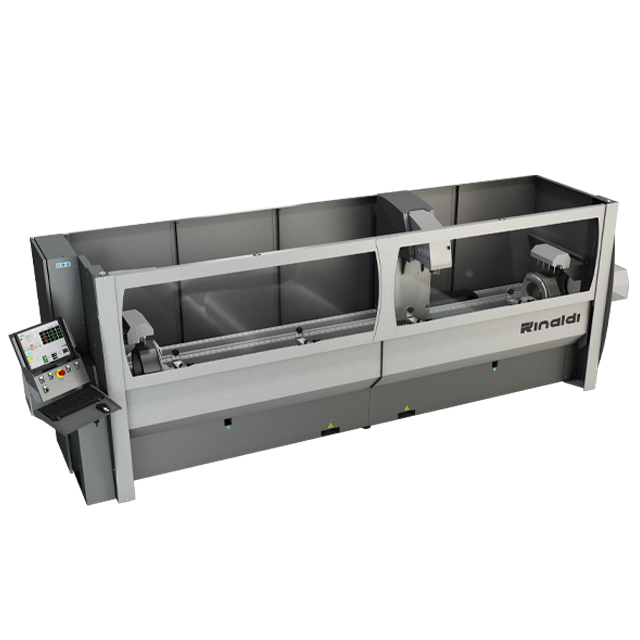

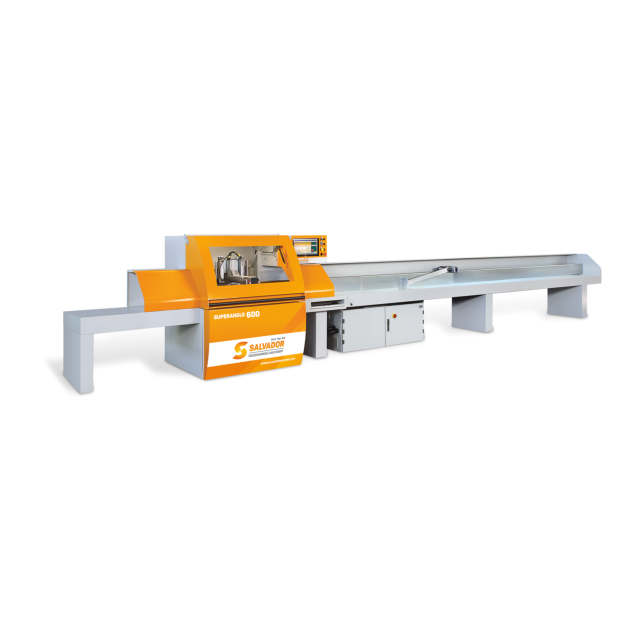

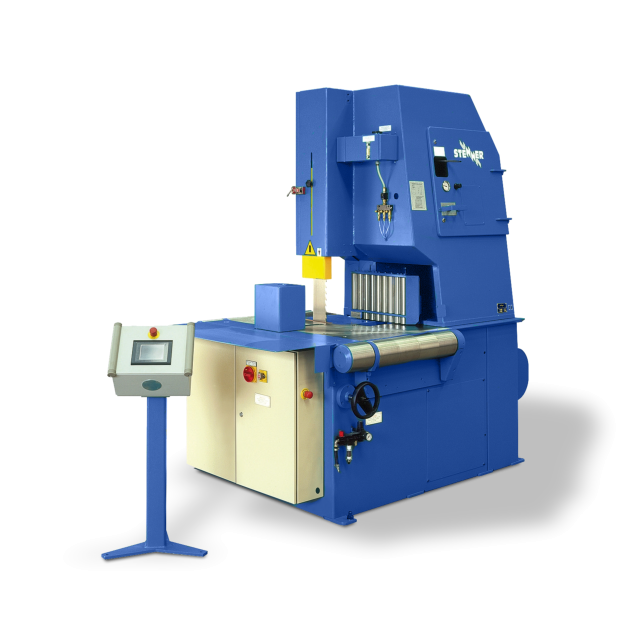

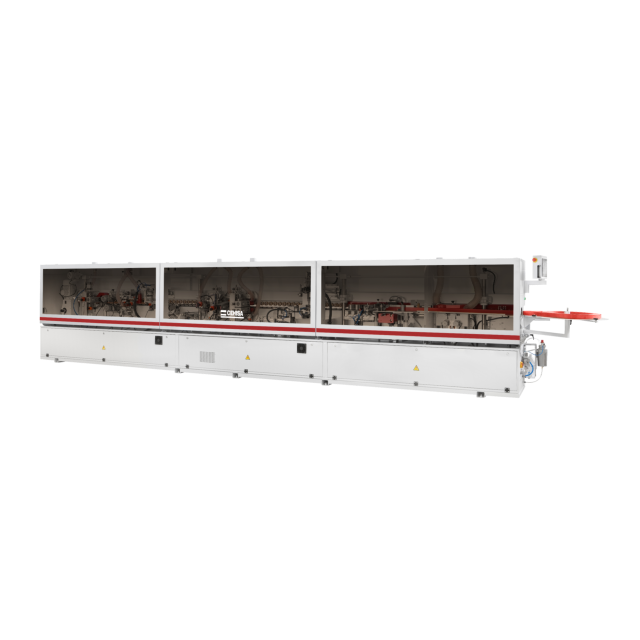

Salvador SuperAngle 'All In One' Automatic Crosscut Saw

Features

- Crosscutting and drilling in one

- Straight and angled cutting

- Optimisation and defecting as standard

- Efficient and accurate production

- Automatic material measurement

- Intelligent clamping

- High speed pusher

- Intuitive graphical operator interface

- Remote machine monitoring and assistance

call 0115 986 5201

Description

The Salvador SuperAngle 600 ‘All In One’ is based on the standard SuperAngle model but incorporates a multi-spindle drilling unit enabling the machine to both crosscut up to +/-70° and drill, bore and countersink components. Compared to traditional crosscutting methods a Salvador SuperPush can increase yield by 15% or more, reduce labour by over 50%, reduce operator skill levels and increase productivity while providing a 100% safe working operation.

Control

The SavlaWOOD optimisation software provides intuitive operator control over with 19” eye level screen and graphical representation of the machine functions, cutting lists and infeed material currently being processed.

Cutting lists can be manually entered directly at the machine, or from an office based PC using a simple Excel spreadsheet macro uploaded using a USB drive or standard network connection.

The powerful optimisation software can manage multiple cutting lists as once, including 5 quality grades with priority allocation and full control over all cutting parameters such as waste percentage, trim cuts etc.

A high performance Numerical Control system manages the material scanning, cutting parameters and finished work piece selection to maximise throughput efficiency.

The main control box for the machine is mounted independently to eliminate vibrations from the machine.

Infeed Loading and Pusher

The heavy duty infeed table is available in a range of capacities. As material is loaded the pusher arm scans the work piece reading its overall length and looking for any luminescent defecting marks. The optical scanning system is fixed and does not require any adjustment for varying timber thickness.

The pusher speed can be regulated within each cutting list reaching a maximum speed of 60 m/min as standard or 120 m/min as an option.

The pusher assembly runs on twin external rectified guides requiring minimal maintenance. A high powered brushless servo motor connected to a steel core toothed belt drives the pusher arm with an accuracy of +/- 1mm or +/- 0.1mm as an option.

To further increase efficiency an automatic chain infeed system is available for continued, uninterrupted feeding of single pieces or stacked timber.

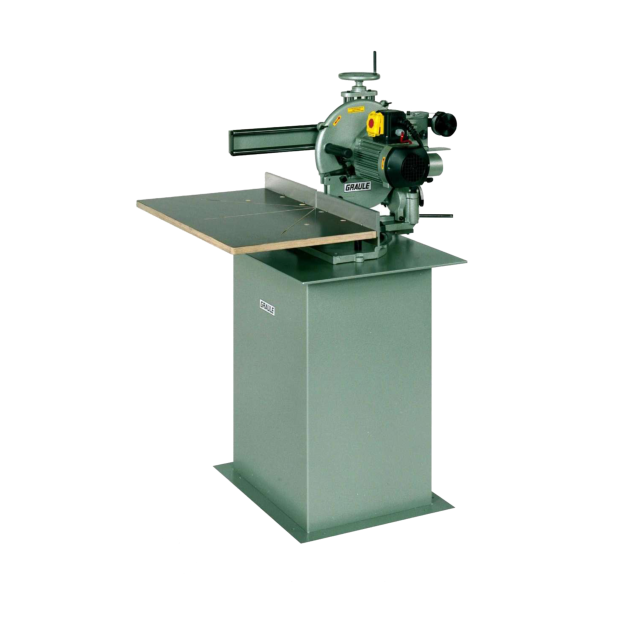

Saw Unit

The saw cycle can be regulated from 0.1 to 2 seconds depending on the thickness and type of material being cut. Four independent electro-pneumatic clamps secure the work piece from above and from the side depending on the angle being cut. The rotating table quickly adjusts between +/- 70° to an accuracy of +/- 1°.

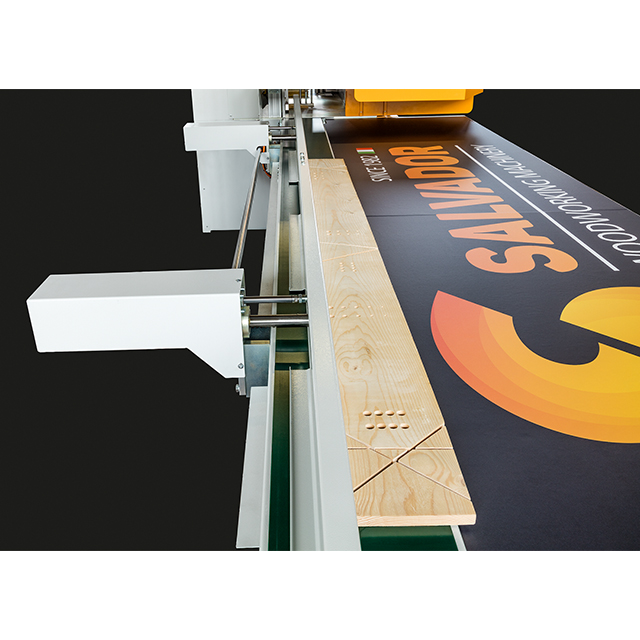

Drilling Unit

The boring head is positioned directly infront of the saw unit. Five independent drilling spindles can be equipped with any combination of tooling from 6 to 16mm diameter at 32mm centres. The entire unit is numerically controlled with independent servo motors for horizontal and vertical positioning.

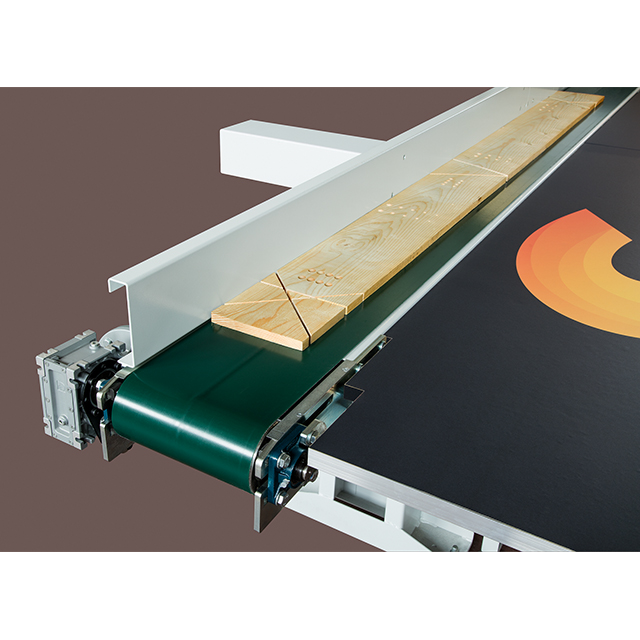

Outfeed Table

The standard 3000mm outfeed table and fence can be replaced with optional outfeed automation for increased efficiency including automatic length selectors for sorting finished pieces, waste trap door for offcut removal and extended collection area with tilt return ejector.

Label Printing

Printing options include simple adhesive label creation at the outfeed station, or inkjet printing directly onto the finished work piece.

Specification

| Saw blade diameter | 600 mm |

| Angle capacity | -70° / + 70° |

| Max width of cut at 0° | 310 mm (160 mm deep) |

| Max depth of cut at 45° | 220 mm (160 mm deep) |

| Max depth of cut at 70° | 100 mm (160 mm deep) |

| Number of boring spindles | 5 |

| Centre distance between spindles | 32 mm |

| Pusher speed | 60/ 120 m/min |

Disclaimer

Our suppliers have a policy of continuous product development and improvement, specifications are therefore subject to change without notice. We can accept no liability for discrepancies in specifications or illustrations contained in our publications or the publications of our suppliers.