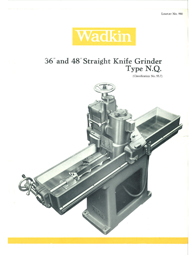

Wadkin NQ Grinder

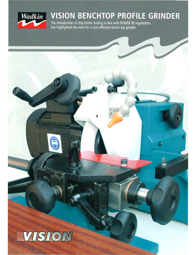

The importance of keeping knives and cutters properly ground, and thus ensuring efficient production from key machines such as planers and moulders, surfacing and thicknessing machines, justifies particular attention being given to the choice of equipment for this purpose.

Long experience with different types of grinding machines in our own Tool and Cutter Department has proved that wet grinding gives better results, and that for the long knives used in planing machine, the most accurate grinding is obtained by mounting the knife on a stationary carrier and traversing the grinding wheel backwards and forwards along the blade.

Specification

NQ 36" - For both flat and hollow grinding of planing knives, veneer knives, guillotine knives etc up to 915 mm (36") long and between 19 mm (0.75") and 105 mm (4.125") wide. Automatic traverse to the grinding head which has automatic downfeed to the items being ground. The machine is designed so that the grinding wheel is constantly flooded with a grinding solution when in use. Canting adjustment to grinding head and knife holder. Two motors 1.5 kW (2 HP to the grinding head). (3 phase).

NQ 48" - For both flat and hollow grinding of planing knives, veneer knives, guillotine knives, etc, up to 1220 mm (48") long and between 19 mm (0.75") and 160 mm (6.25") wide. Automatic traverse to the grinding head which also has automatic downfeed to the items being ground. The machine is designed so that that grinding wheel is constantly flooded with a grinding solution when in use. Canting adjustments to both the grindng and the knife holder. Two motors 1.5 kW (2 HP) to the grinding head (3 phase).

Information