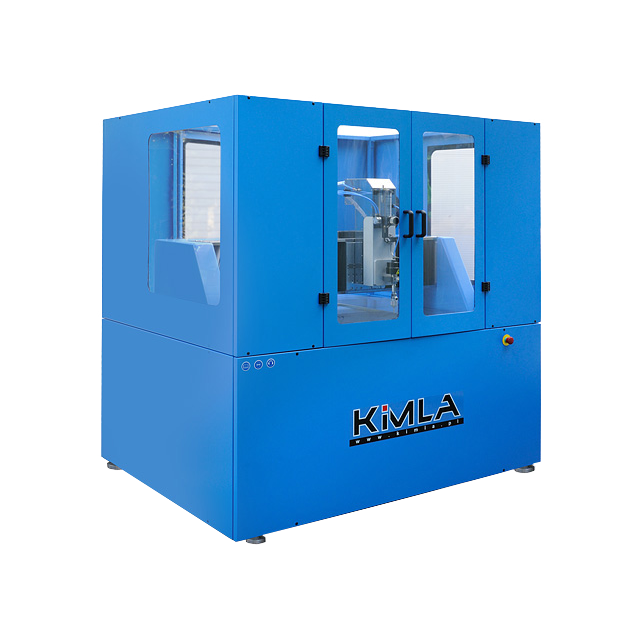

Kimla StreamCut 5 Axis CNC Waterjet

Features

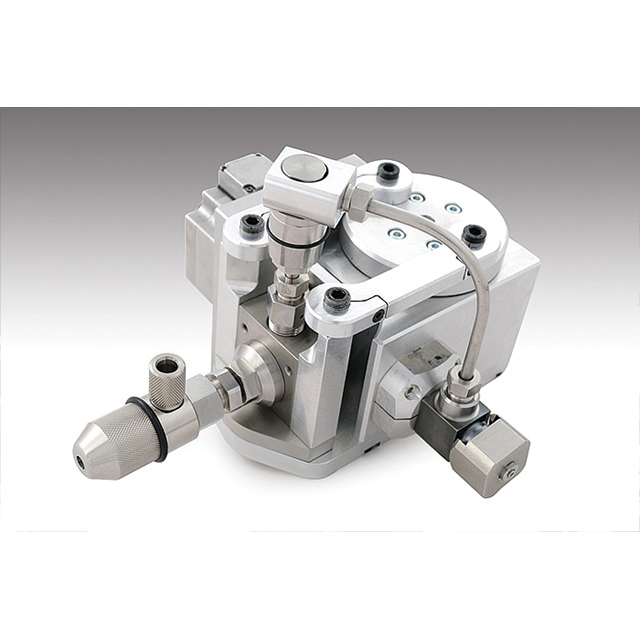

- 5 axis cutting

- Cutting width less than 1 mm

- Material thickness up to 200 mm

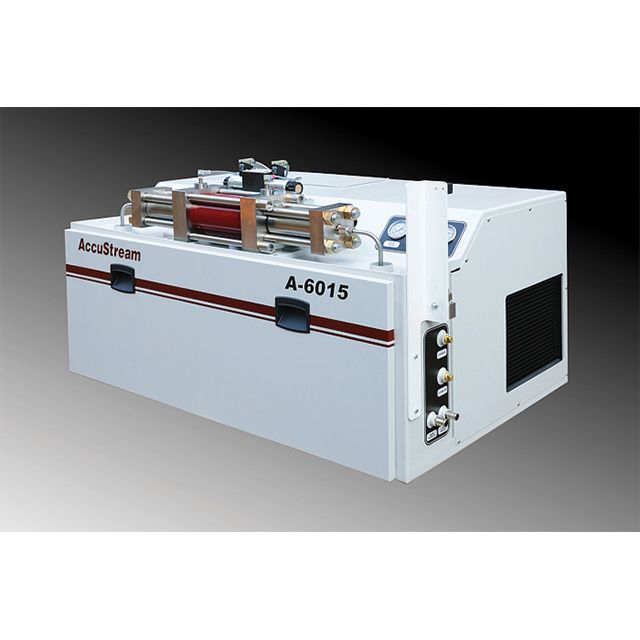

- Powered by Accustream

- Cut a variety of materials, hard and soft, from foam to stone

- Low pressure piercing system prevents damage to brittle materials

- Waterjet specific toolpath creation and feed regulation

- Nesting function for optimising component position within material

- Full water bath with air bag displacement chambers for raising/ lower level

- Dynamic Vector Analysis (DVA) system for smooth regulation of the feed speed

- Each machine custom built to individual requirements

- Digital AC digital servo motors

call 0115 986 5201

Description

Waterjet – innovative cutting technology – Abrasive Waterjet technology is the most innovative of all currently available cutting technologies. Waterjet machines can cut practically any material, ranging from the very soft such as foams, gels, sponges, through to harder materials such as plastics, composites, rubber, leather, soft metals such as aluminum, brass, copper, carbon steel and stainless steel, and ending with heat-resistant and hardened steels, ceramics and cemented carbides. Waterjet can also cut glass, stone, granite, marble and ceramic tiles which are among the hardest most brittle materials encountered in industry. The thicknesses of the cut materials reach up to 200 mm, which is inaccessible for the majority of other cutting technologies. One of the principle advantages of Waterjet machines is that the width of the cutting gap is very small, less than 1 mm, which allows cutting out of extremely intricate shapes and precision cutting of corners.

These machines are used primarily in metal and stone industries. Waterjets are further exploited to cut building components such as stairs, window sills, kitchen or bathroom worktops, elements of tombstones and monuments etc. The five-axis version allows the inclination of the head in such a way as to enable cutting with an inclined wall. Five-axis Waterjets are used in the metal industry, where chamfering is required for welding. The stream of water is combined with abrasive and can pierce through the hardest materials from the inside so that it may cut the object closed without a need to enter into the material from the outside, as is the case of cutting by wire

The rigid construction of the water bath and self-supporting structure – The innovative construction of the water bath provides a very rigid and stable foundation for all Kimla Waterjet machines. It provides not only excellent rigidity and resistance to any deformation caused by the weight of the water pressure, but also enables a truly self-supporting compact machine. Thanks to this the machine does not require any special foundation.

Low pressure piercing – Some materials, such as glass, stone or ceramics are prone to cracking and splintering during cutting. To prevent damage to the material and to provide economical processing of materials, Kimla machines have been equipped with the option of low pressure piercing, which can reduce the jet impact force when piercing the material.

Air bag – The innovative use of displacement chambers in the Kimla machines greatly reduces noise. This applies particularly to the stream of water while in the air. The water covering the minimal distance (about 2mm) from the nozzle to the material generates the loudest noise. To prevent this, Kimla Waterjet machines are equipped with air bags, displacement chambers, which enable the water level to be raised or lowered during cutting.

Adjusting the amount of abrasive – Kimla Waterjet machines are powered by Accustream regulators for the smooth adjustment of aggregate to the head. The adjustment of aggregate flow greatly increases the economic running of the machine.

300 kg abrasive tank with the hopper system – Abrasive tanks, which are supplied as standard equipment, have a capacity of 200 litres, which enables a single fill of 300 kg of aggregate providing many hours of cutting without disruption.

Table made of strips of galvanized steel – To support the material being cut the Kimla Waterjet machines have been equipped with a segmented grid of galvanized steel strips embedded in comb handles. This allows individual strips to be replaced at any time as required.

Stainless steel finishing – Parts of the machine exposed to abrasion are finished with stainless steel to ensure extended life and aesthetic of the machine.

All the drives protected against water – Water and aggregate, always omnipresent in Waterjet machines, can lead to elements exposed to damage and corrosion. To prevent this, covers protect all drives from direct exposure to sand and water. These solutions help guarantee the long-term operation of the machine.

Ergonomics of work – Thanks to the compact design the operator has easy access to the water bath and machining area for loading/ unloading parts.

Toolpath generating software – The dynamic control of operating speed in Waterjet machines is extremely important. The speed should depend on the shape of the toolpath. The Kimla software has the ability to generate toolpaths automatically on the basis of dxf, plt files, etc., and enables drawing elements in the built-in editor. The toolpath generating module automatically creates the cutting path taking into account the dynamics of speed and the diameter of the cutting jet. Other Waterjet machines on the market use standard router control systems which restricting the overall processing speed.

Digital AC Servo Drives – The Kimla Waterjet machines are equipped with the latest AC servo drives with vector control and positional feedback to control the movement of the head continuously. This enables reliable and repeatable mapping of the machined shape. The drive control is powered by Kimla’s Dynamic Vector Analysis (DVA) system allowing smooth regulation of the feed speed when cutting complex shapes.

RTE Interpolator – The Kimla machines have been equipped with regulators which constantly set the position, speed, torque and acceleration, which is possible thanks to a very fast data transmission between the interpolator and servo drives using real-time Ethernet (RTE). As a result, the dynamic accuracy of machines is significantly increased, which is particularly evident at high speeds and complex shapes.

Electronic gate angle correction – Kimla has developed and implemented an electronic system for correcting the angle of the gantry, which automatically sets the correct angle. This has enabled the gantry to be positioned along the narrower working side providing convenient operating.

Convenient movable control panel – Kimla machines are equipped with a mobile control unit which can be ergonomically placed as required by the operator.

Operating speeds and accelerations – Most users of other Waterjet machines are convinced that the machines are slow and do not develop high-speed machining. However, the advancement of Waterjet technology is rewriting the standards. Thin and relatively soft materials, such as aluminium, ceramics, etc. can be cut much faster than a few years ago. For this reason, the cutting speed limit does not often result from the Waterjet technology itself but from the restrictions arising from the capabilities of the control system and the drives. Therefore, Kimla machines are equipped with drive software achieving operating speed up to 900 mm/sec.

Nesting – Software for optimising the distribution of components on a work piece makes best use of the material. Depending on the user requirements there are two versions of the system to achieve varying degrees of optimisation. After selecting shapes and their quantities to be cut the user gives the size of the work piece and the software automatically distributes the detail onto the sheet.

Powered by Accustream – Generally regarded as the best available on the market with low running costs, Accustream pumps power all Kimla Waterjet machines. High pressure cylinders with ceramic pistons provide performance of 4.16 l/min at 50 HP running 4150 bar, with a stream up to 1.02 mm.

Independent, external cooling system – The pump is equipped with an external closed circuit oil cooling system which significantly reduces the use of water that is consumed only for the cutting process. This allows the heat exchanger to be moved outside, reducing noise and space requirements.

Specification

| Number of axes | 5 |

| X axis movement | 2100/ 3100/ 4100/ 6100 mm |

| Y axis movement | 1100/ 1600/ 2100/ 2100 mm |

| Z axis movement | 200/ 250/ 300 mm |

| Maximum cutting thickness | 200 mm |

| Maximum speed of movement | 900 mm/sec |

Disclaimer

Our suppliers have a policy of continuous product development and improvement, specifications are therefore subject to change without notice. We can accept no liability for discrepancies in specifications or illustrations contained in our publications or the publications of our suppliers.